A lot of people I know like to name their bicycles. A friend of mine calls her bicycle Oliver, so I decided to make her a little name tag for her bike.

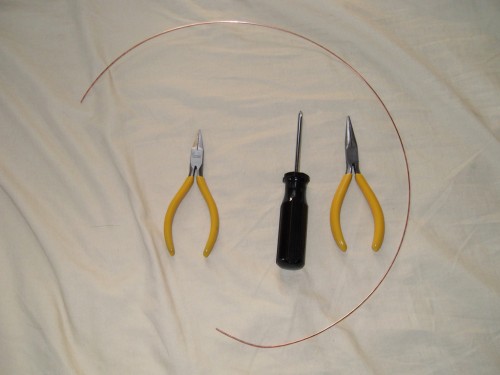

Things you will need for this project

26g Brass Plate (polished to a high shine)

jewelers saw

burnisher

rubber cement

print out of design you want to cut out

needle vise

drill bit

eye protection

dust mask

Start by cutting your brass plate down to the size needed for the project, polish it to a high shine (I used various sand papers working down to finer and finer grit).

Cut out your design, leave some space around the edges.

Apply rubber cement to your (clean and dry) brass plate, then apply your design

Use the burnishing tool to get all the air bubbles out and to make sure every single part of the design is fully pressed to the plate.

Wait till the rubber cement sets up. This takes about five minutes.

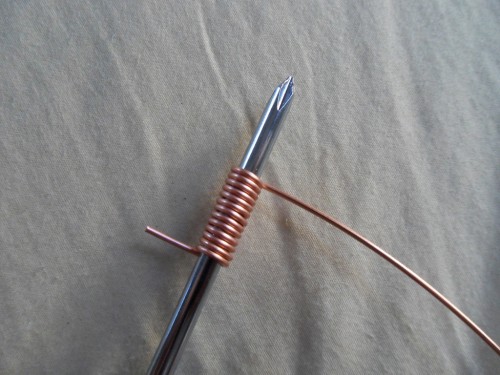

Get your pin vise, and choose a drill bit that can drill through metal, make sure your drill bit is small enough to fit inside the portion of your design you want to cut out.

These tiny little drill bits are very fragile, but sure not to put too much force on the bit as you drill the holes. Drill your hole straight down, making sure to keep the drill perpendicular to the metal.

When you are done you should have little holes in each part of the design you want to remove.

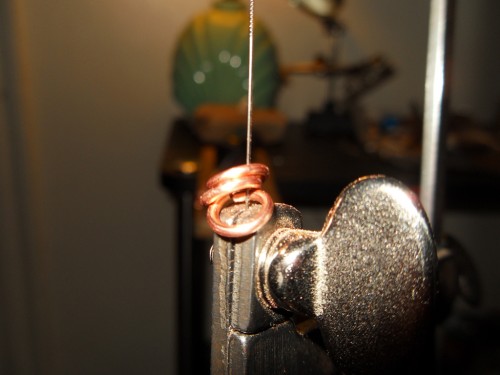

You are now going to thread your jewelers saw, affix the blade in the bottom half of the saw, then thread your saw blade through one of the hole you just drilled out. Carefully affix the top half of the blade making sure that the saw is properly tensioned. Its easy to break a blade here so be sure you have eye protection. Also because we are about to make a lot of metal dust its a good time to put your dust mask on.

Hold your saw straight up and down, and make smooth easy strokes using the saw to slowly cut around the design printed on the paper.

Be careful not to pull down too hard or you can bend fragile parts of the design. After you cut out each place you will have to detach your saw from the frame and move to the next hole.

When you are done carefully peal off all the paper, and rub off any rubber cement left over, give the piece one last polish with a cloth. I rounded off the edges and gave the edges a good taste of the burnisher to give it a high shine.

To affix it to your bike you can gently bend it over the top tube, and affix it with jb weld, or other strong epoxy. You can also drill small holes in the corners and affix it with screws, or even use very strong 3m double sided tape.

If you don’t want the brass to lose its shine you can spray it with shellac, or give it a clear coat.

Its a great way to give your bike a little individuality.