I needed a rubber stamp to mark the packages I was sending out from my etsy store, so I figured…why not make one.

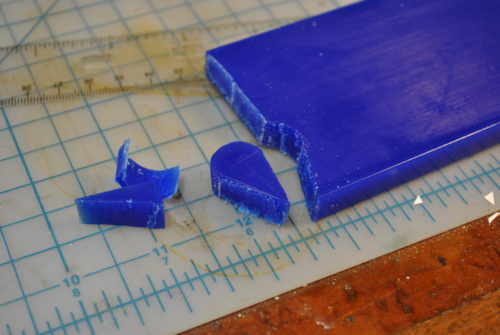

I didn’t have any stamp rubber laying around, or the tools to carve it…so I started by making both of those.

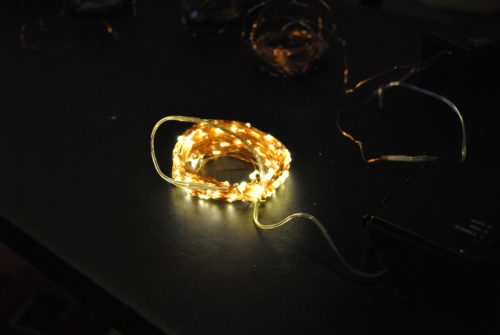

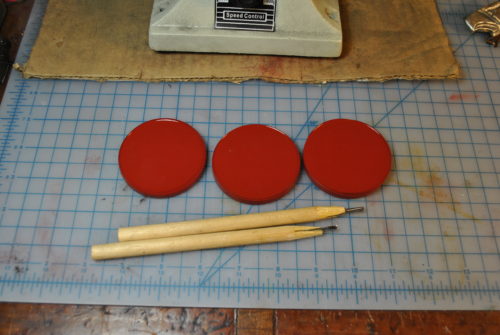

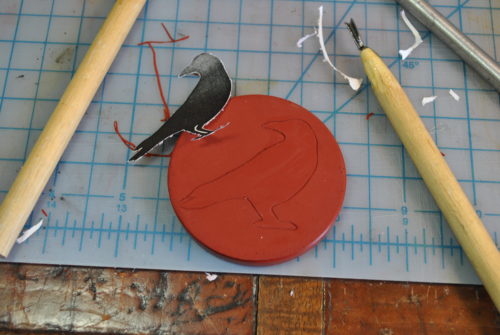

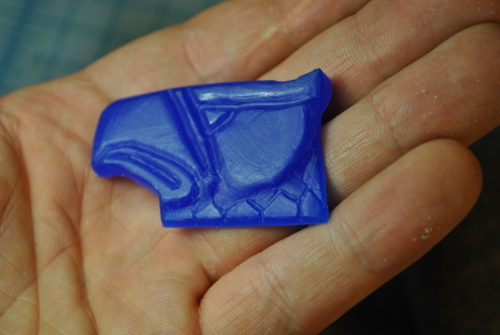

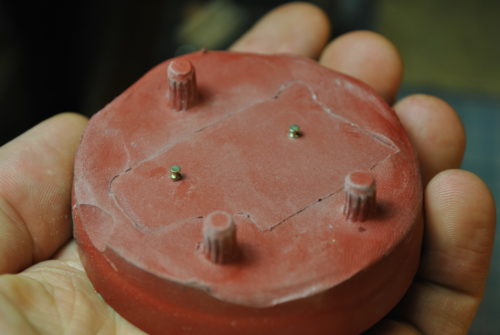

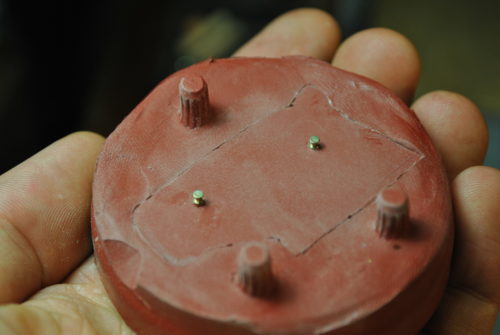

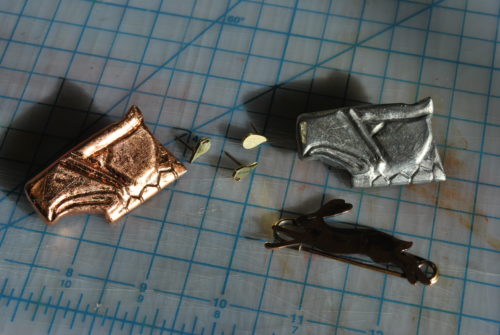

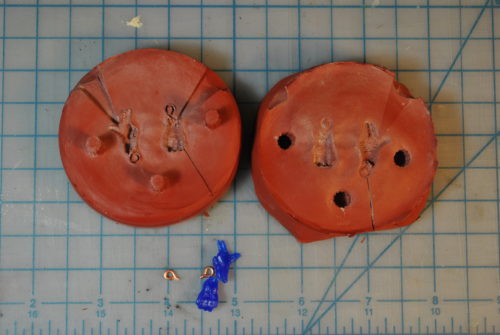

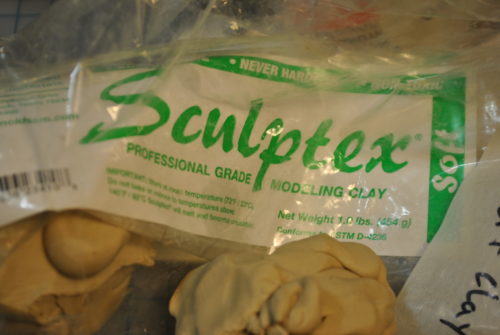

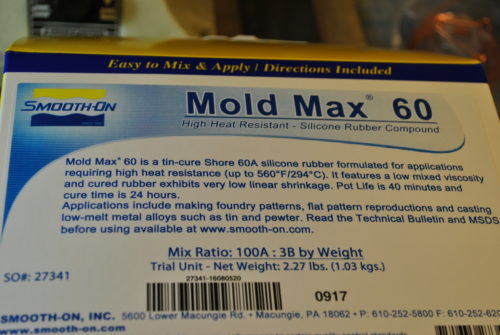

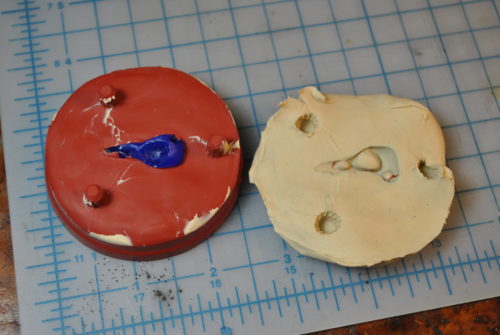

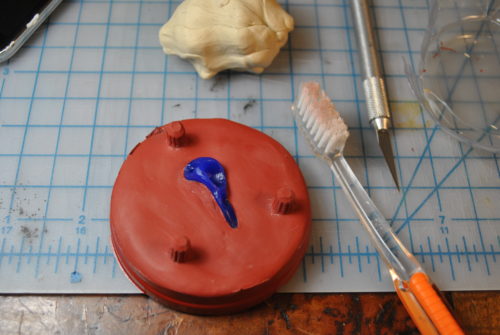

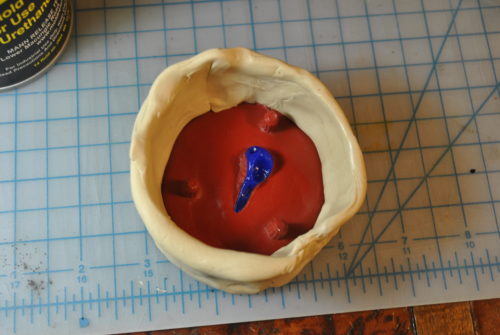

I had a little bit of mold max 60 left over from previous projects, but not enough to make anything with, so I cast some small pucks of it to carve. Nothing special, just filled some plastic caps I had from jars and made three pucks. See here for how to use Mold Max 60, or just buy some stamp rubber from any craft store, its super cheap. I just like doing things with what I have on hand.

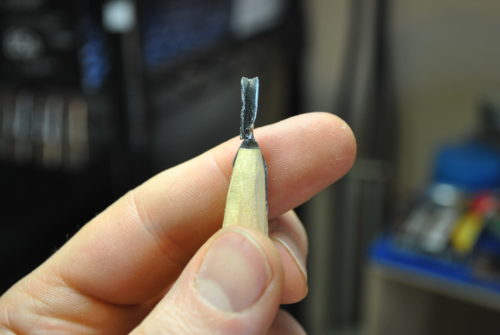

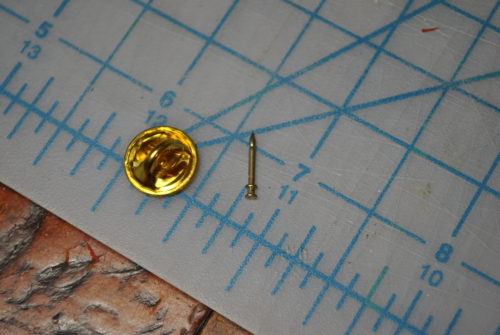

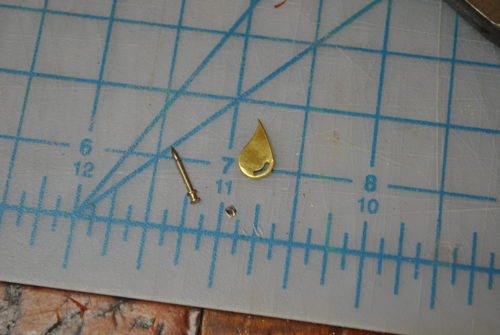

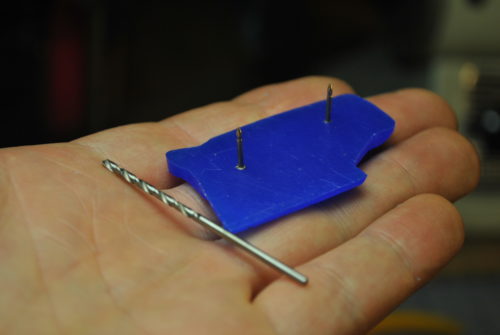

But I didn’t have any tools…so I took some sheet metal I had, and bent and sharpened then until they looked like the carving tools I had looked up on the internet. I used a technique very similar to how I made the wax carving tools.

To get the larger more shallow carver I used a metal rode to bend the sheet around after sharpening it. The vice grips are just holding the sheet while I hammer.

I put sharpened up some dowel rods and put some epoxy in there to keep them strong, only made two, and ended up doing a fine job of carving.

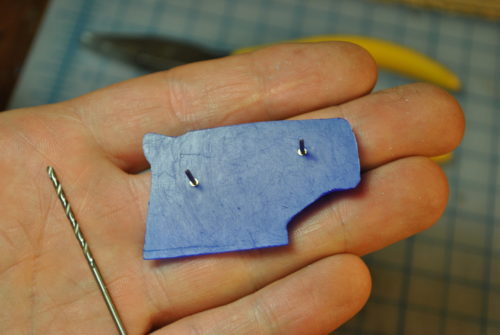

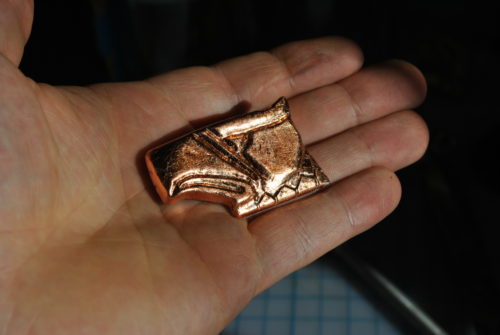

I started by sanding down one puck to get rid of the shine left by the casting process.

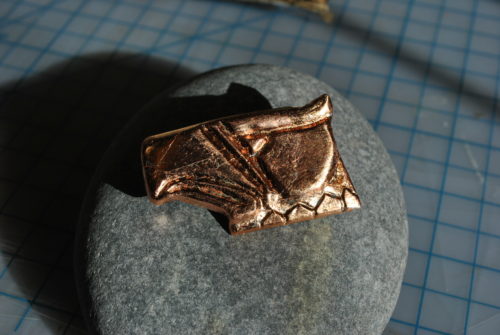

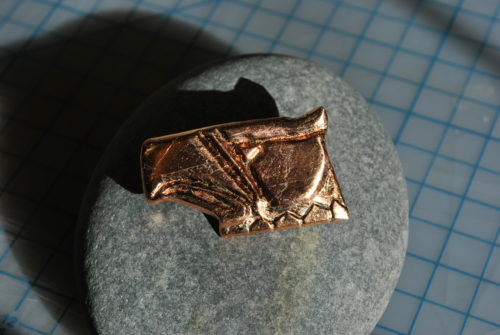

Then I printed out a template and got to carving. The tools woked well, but I realized half way through, that for such a simple design o could have just cut the shape out with a saw.

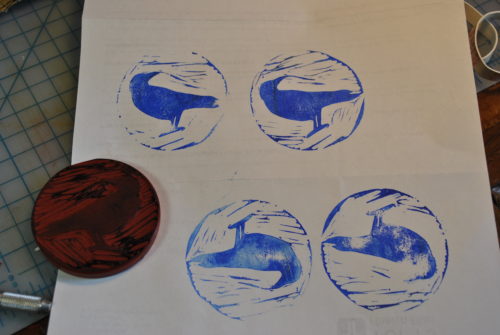

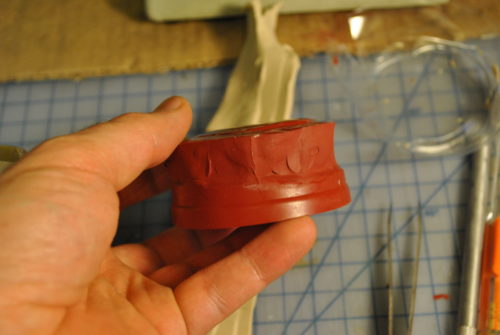

The floppyness of the rubber was making it hard to get good stamps. So I built a backer.

I had some aluminum clad black acrylic that was nice and stiff, so I cut a circle out and glued it and a small wooden handle to it.

Then I did a couple more stamps, cutting away any rubber that was messing up the design.

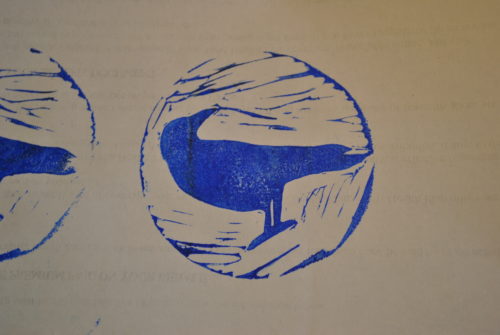

I realized the middle wasn’t getting inked because the ink pad was slightly warped, but I really liked the way it made a sort of cloud pattern inside the crow.

Came out well, and I still have plenty of materials to try and make some fancier ones.

Do you want to help me continue to bring you great projects, while also getting great rewards? Then support me on Patreon!

Thank you!

‘

‘