My mom has this habit of every once in a while gathering up all the junk in her house she doesn’t want and sending it to me in a box. It is both very sweet, and frustrating. I never know what to do with all the stuff she sends. Recently she sent me a little power stick USB thing. Its one of these screen printed branded gizmo’s you would pick up at a conference, this one stores up energy from a USB port, and then you can charge up phones or e-readers or whatever.

You plug it into a USB port, it charges up, and then you recharge other things. Neat, but boring. I wanted to see if I could make it cooler, by adding some solar cells to charge the battery with the sun.

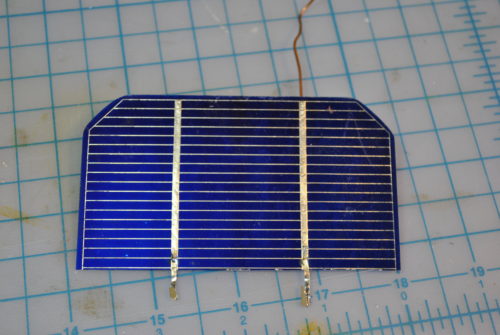

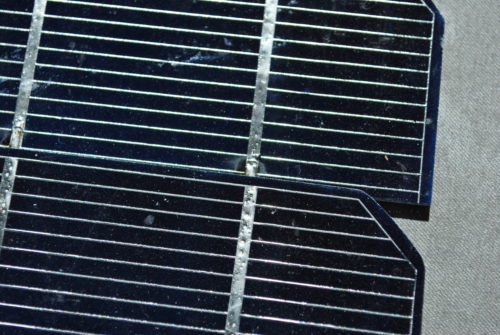

You will need a soldering iron and a multi-meter for this, both are pretty cheap and I think I picked these up years and years ago when Radio Shack was still a thing. I also have been sitting on these solar cells I got years and years ago. They were broken, so I got them for free from a Japanese solar cell maker that I had written a letter. You can find solar cells on E-bay.

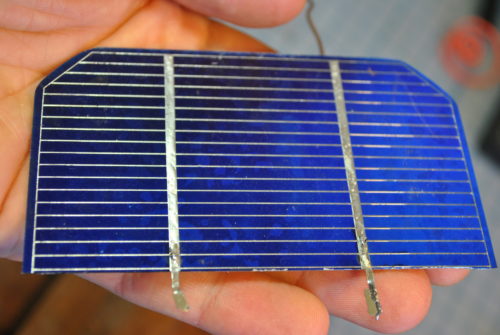

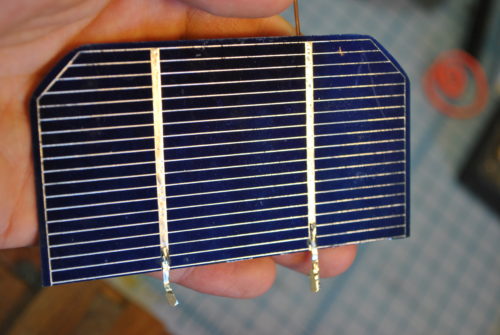

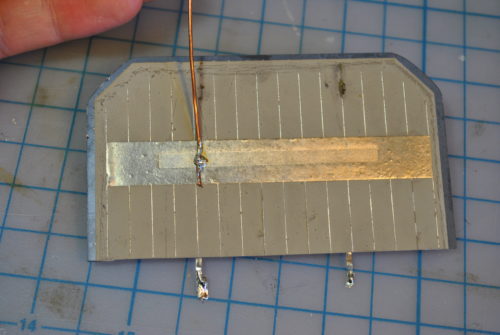

They had some foil soldered on them, and I used the little tabs to connect them. Solar cells work a lot like batteries. Each cell pumps out about .5v volts, and you can connect them the same way you connect batteries. On my cells the front of the cell is the positive side, and the back is the negative side (just like the + and – of a battery), it could be different for yours. Looking at the back of the little battery device it shows that it needs 5 volts to charge it. So I will need to create more than 5 volts to charge the battery. But I don’t want something so high voltage that it fries the thing. I will be shooting for 6 volts.

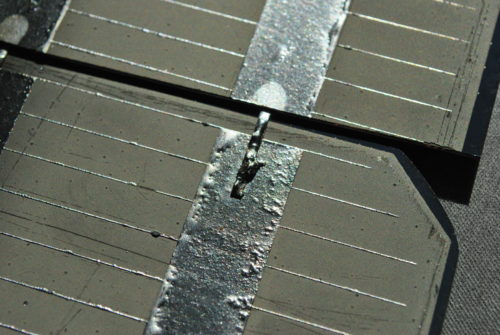

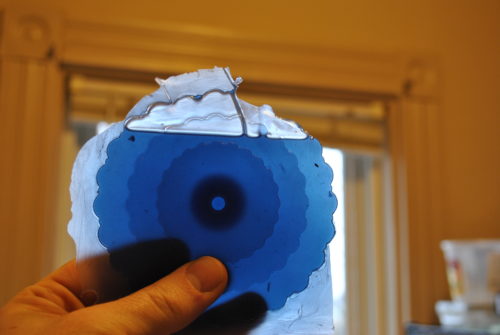

If you hook them up in series (positive to negative) you add the voltage. If you add them in parallel (positive to positive, negative to negative) you add the amps. So if each of my cell puts out about .5 volts, I will need to hook 12 cells up in series to get the 6 volts to charge my battery. (its pretty easy to size a solar array to any power requirements you need, see here for more info)

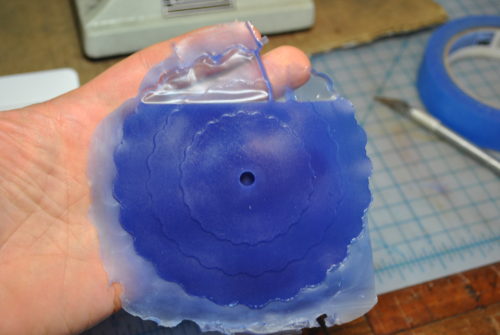

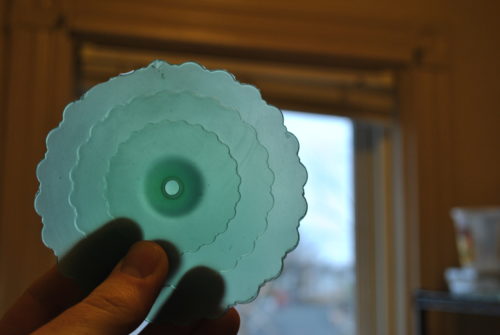

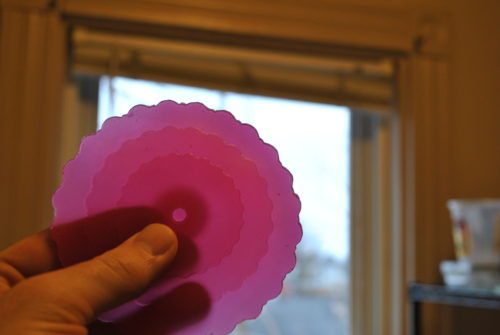

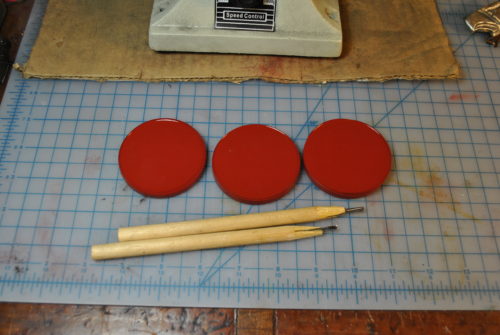

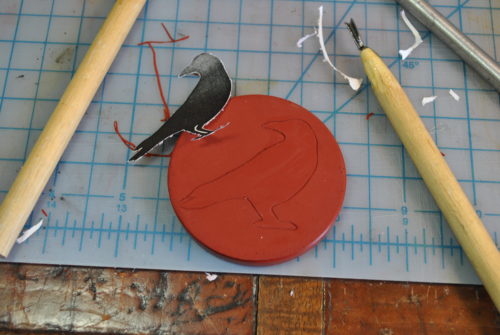

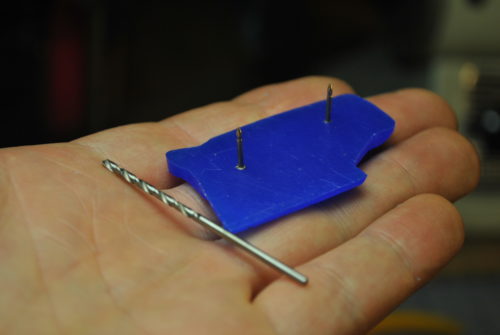

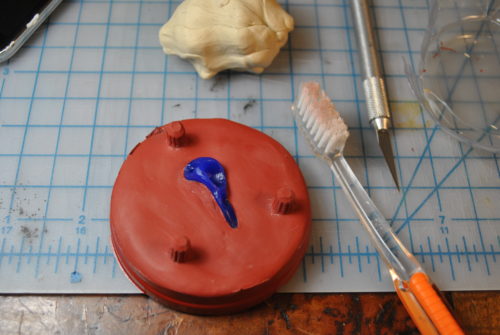

After a little work with the soldering Iron I had two arrays of 6 cells. Cells still work just fine when broken, but they are very very fragile, you need to be very careful when handling them, its very easy to snap them.

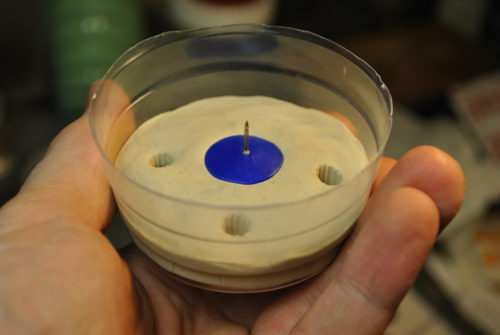

I used a small piece of plastic to hold the cells, these are only going to be used inside so I didn’t bother to seal them up. I used two tiny pieces of double sided tape to just keep them from sliding around.

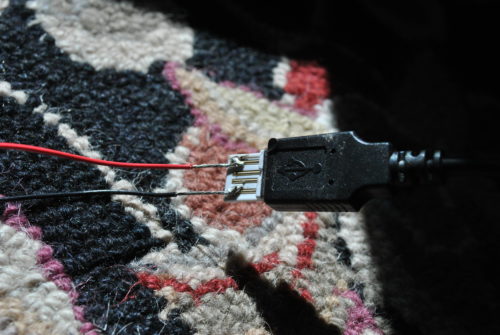

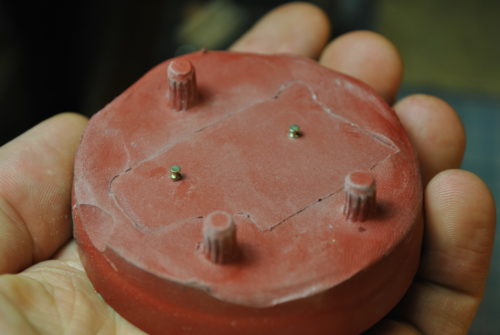

I also had this old usb dock I wasn’t using, it will be perfect to connect the panels to the battery.

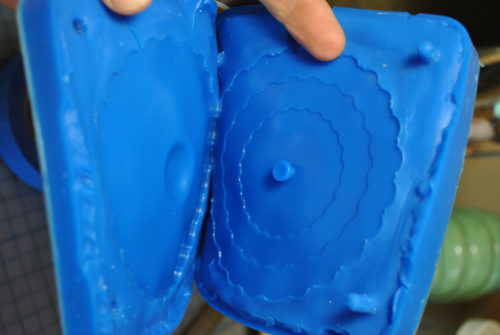

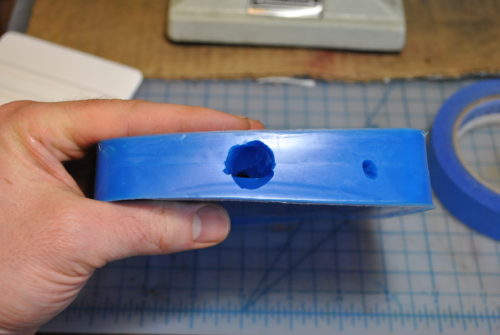

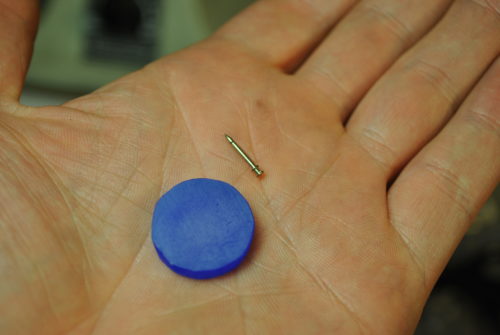

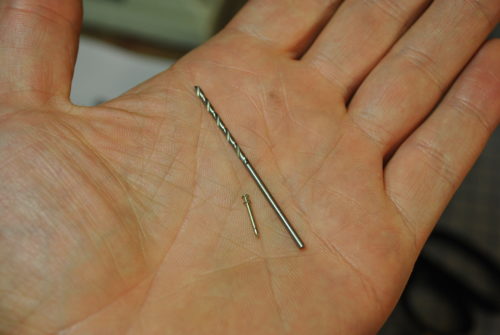

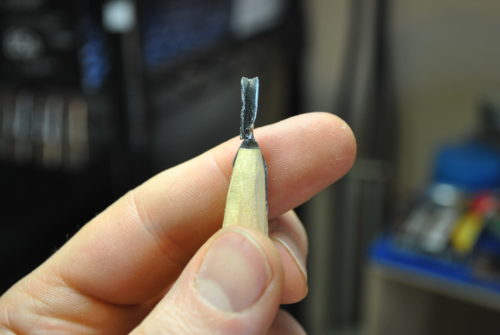

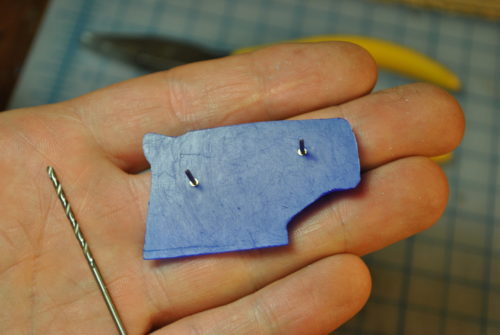

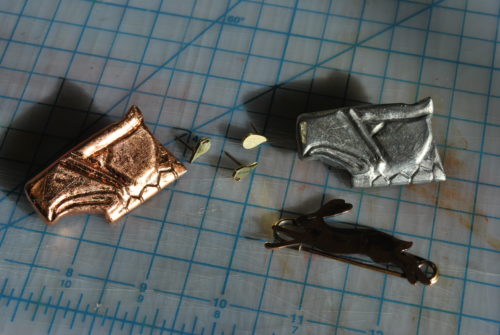

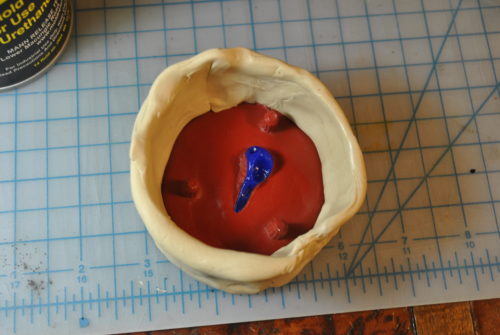

The only problem is that the usb connector isn’t going to be easy to connect wires to with the housing on it. A little work with a jewelers saw fixed that.

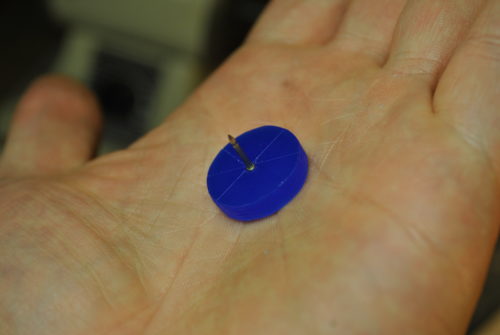

be careful not to cut all the way through, you just want to remove the metal housing to expose the connectors.

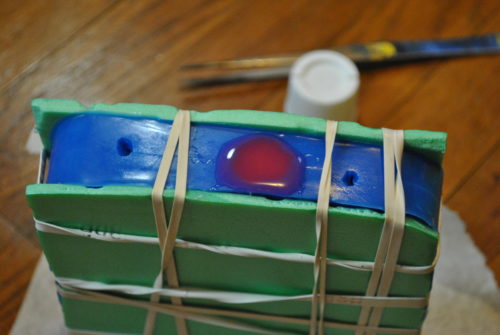

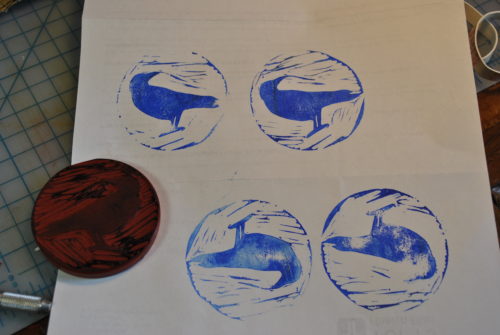

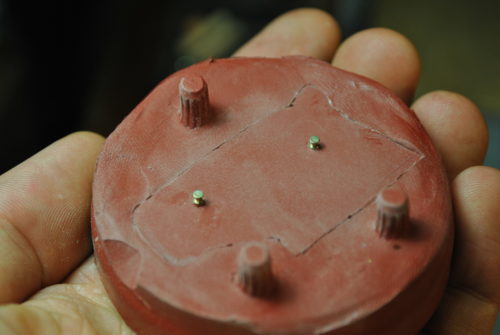

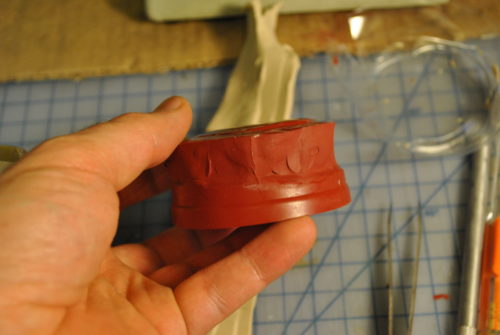

I put the red wire (from the top of the array) on the far right connector, and the black (from the bottom of the array) on the far left.

here you can see how the top of the last cell on the left array is attached to the bottom of the right array

The array actually pumps out about 7 volts when nothing it attached to, but puts out 5.22 when the battery is attached. Which is just about perfect.

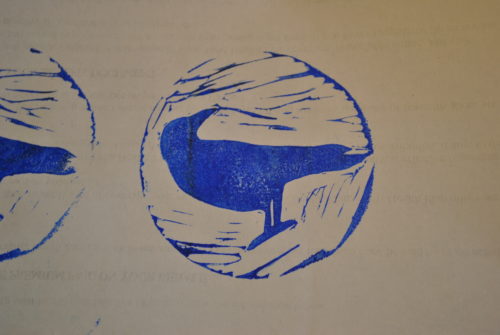

I plugged it all together, put the cells in the sun and whalla! The charging light turned out. The nice thing about these little battery packs is that they have their own charge controller in them, once they are full they just stop taking a charge.

I left it in the sun for a couple hours and when I came back the little green light was on indicating that the battery was full. I plugged it into my phone and it started charging my phone.

I was able to charge my phone up a couple times before the battery went dead, but all it will take is another bit of time in the sun, essentially making my phone solar powered now.

Do you want to help me continue to bring you great projects, while also getting great rewards? Then support me on Patreon!

Thank you!